Introducing FS273M System

FS273M metal system – the next generation of FS271M – offering single or dual laser options for commercial orders. Farsoon’s FS273M is designated to address productivity, cost-efficiency, and industrial workflow in the metal additive manufacturing. With an industrial-sized 275×275×355mm build envelope, the FS273M is a powerful and versatile production tool of larger volume parts with a wide range of industrial metal materials.

Industrial Applications with FS273M

As our next generation of our medium-sized metal system, the FS273M system has been through years of optimizing of the productivity, machine performance through continuous collaboration with our industrial partners; meanwhile keep pushing the true industrialization of the metal additive manufacturing by reducing customers’ cost of operation, especially for tight margin industries like molds & tooling.

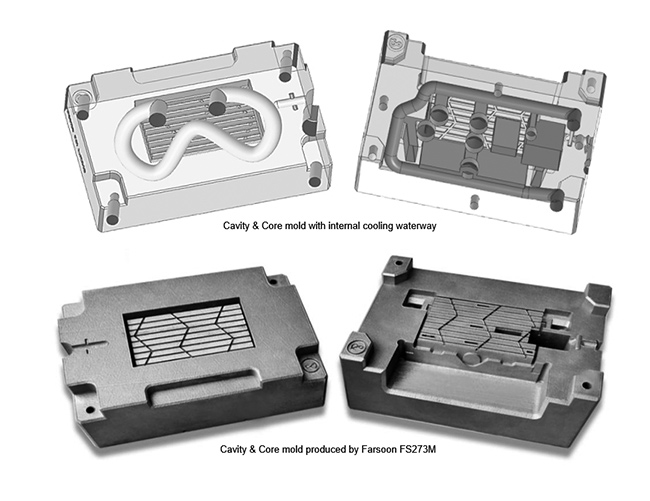

Cavity & Core Injection Mold

Machine: FS273M-2

Material: 420 Stainless Steel

Build time: 20 hours

This set of cavity & core mold is the key components in the whole injection molding system to produce router shell. Because of its complex structure with internal cooling channels, the traditional production takes more than 2 weeks including machining, assembly and post processing. Now with Farsoon’s 273M System, the engineers are able to combine multiple parts into a single part with good material melting uniformity. It also achieved a reduced lead time of only 48 hours and improved surface resolution without the need for further post-processing.

Request for a Quote: info@voxelsa.com