By taking the pain points from our customers which focus around productivity, safety, stability, and ease of use, it led us to co-innovating with Farsoon’s key partners from various industries such as aerospace and tooling, Farsoon has created a system truly suited for industry. By working closely with these industry partners, the FS301M was designed to meet desired user operations, including production speed, powder management, machine factory layout, quality of finished parts, ease of operation and serviceability.

Farsoon’s openness to truly co-innovate by working with industry customers allows FS301M to be a truly user-friendly system. Created to meet the demanding requirements with an end use aviation customer in the U.S., the testing data from the joint process development on the FS301M for Ti6Al4V Titanium shows industry-leading performance for additive and near-wrought properties.

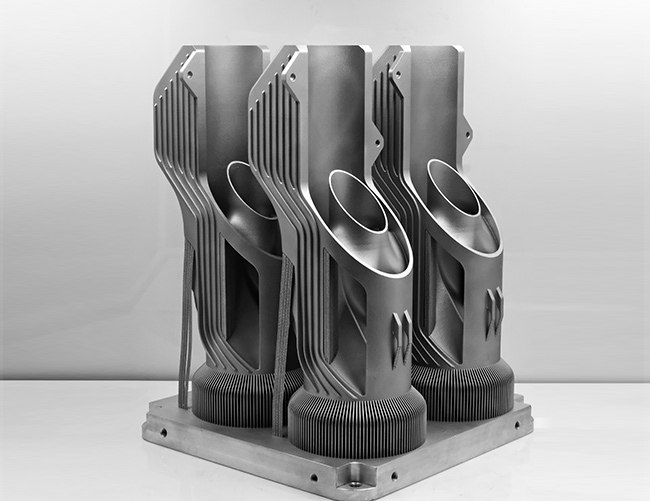

AUV Heat Exchanger Component

Machine: FS301M-2

Material: Aluminum

Size: 158 x 136 x 360 (H) mm each

Layer thickness: 0.05 mm

Build Time: 96 Hours

Thanks to the advanced Farsoon metal additive manufacturing, engineers are able to explore brand new design of this heat exchanger component with structural integration, light-weighting and mechanical strength. With this innovative design, the engineers are able to achieve total build time of 96 hours with 0.05mm layer thickness. The as-printed part features excellent surface quality that will only require easy post-processing, like heat-treatment, wire-cutting and sand blasting.

Request for a Quote: info@voxelsa.com