Fluorinated Ethylene Propylene (FEP) Resin

The Light-Curing FEP Release Film is made from fluorinated ethylene propylene (FEP) resin which gives higher flexibility and less stiffness to the sheet. The film sheet comes with wear resistance, heat resistance, and non-viscosity characteristics which ultimately enhance the outcome of your 3D-printed items.

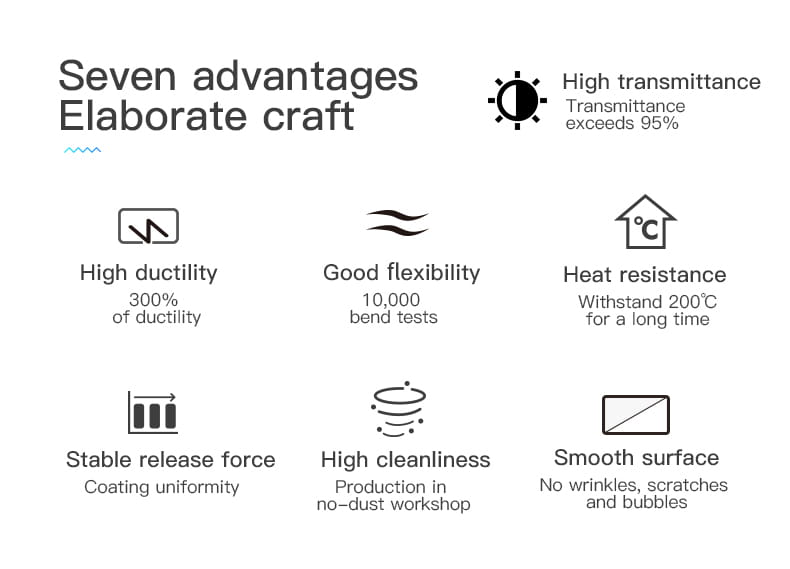

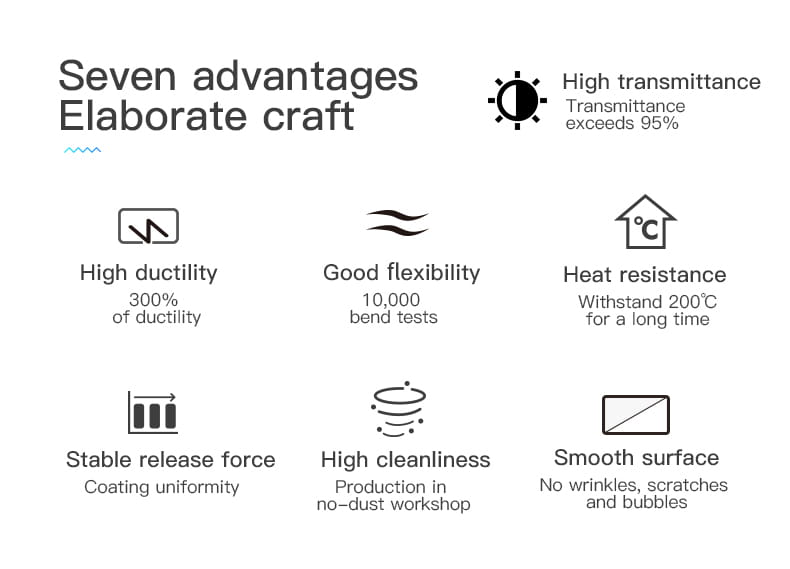

7 Key Advantages of the Film Sheet

The light-curring FEP release film provides seven key benefits in 3D printing, i.e., high transmittance, high ductility, good flexibility, heat resistance, stable release force, high cleanliness, and smooth surface. This gives you a better 3D printing experience and quality outcome of the 3D-printed item.

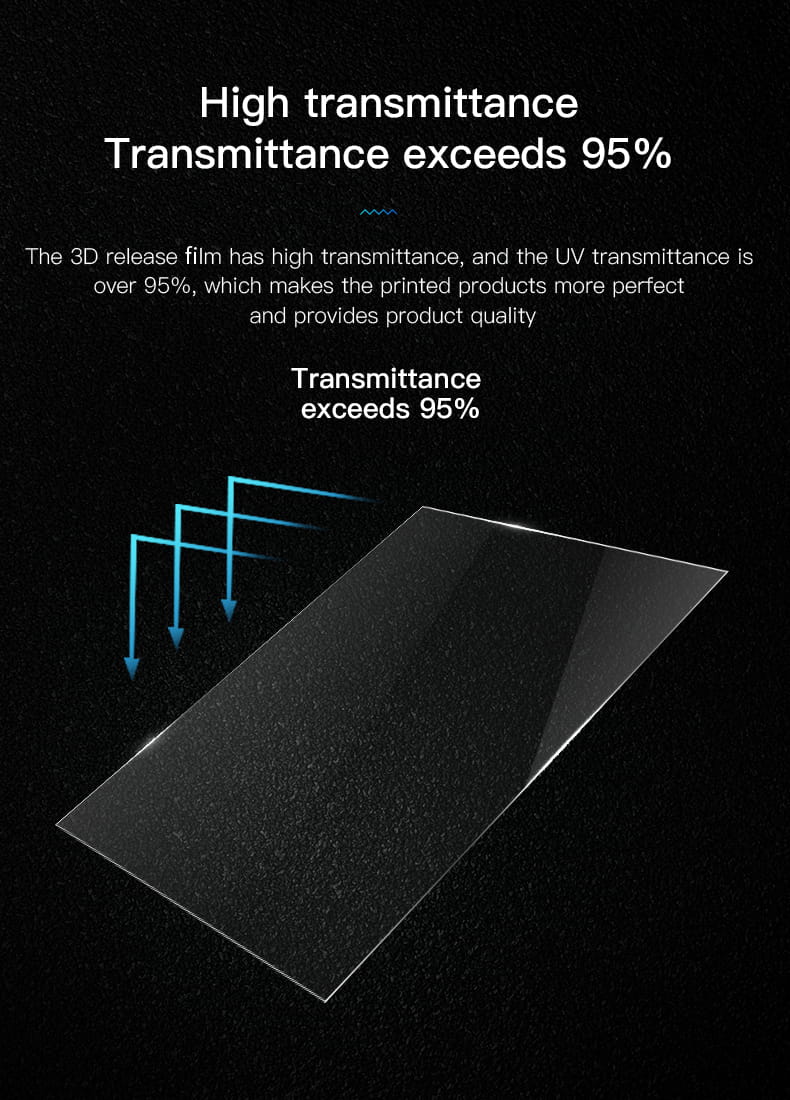

High UV Light Transmittance

The film features very high transmittance of ultraviolet (UV) light that exceeds 95%. This positively impacts the quality & perfection of your 3D-printed item and you print exactly what you want.

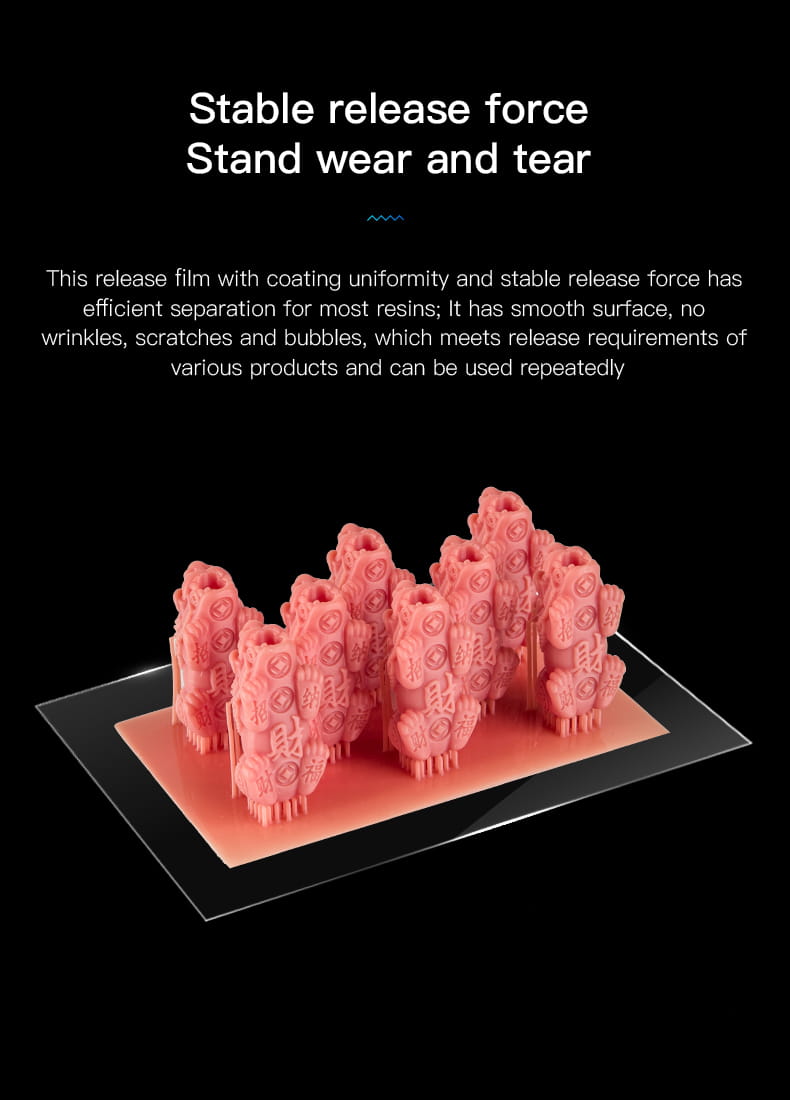

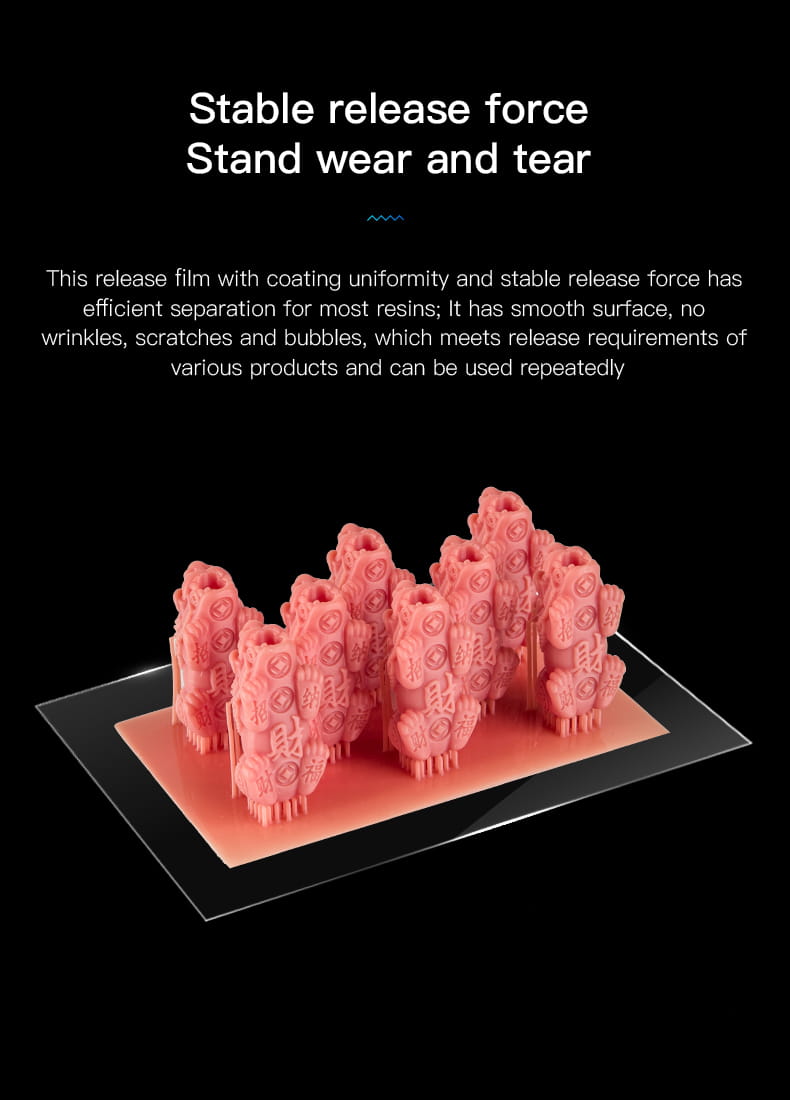

Stable Release Force

The FEP release film allows stable release force due to its coating uniformity. It also has a smooth surface without any wrinkles, scratches, or bubbles. As a result, the separation of the resins becomes very efficient and easier in most cases. The FEP release sheet can be used repeatedly as it is susceptible to all kinds of wear and tear during the 3D printing process.

Good Flexibility & Excellent Ductility

The light-curing FEP release film comes with very good flexibility. The sheet has passed 10,000 bend tests yet still it doesn’t show any signs of deterioration. Similarly, the FEP release film features a 300% ductility attribute which makes it less susceptible to breakage.

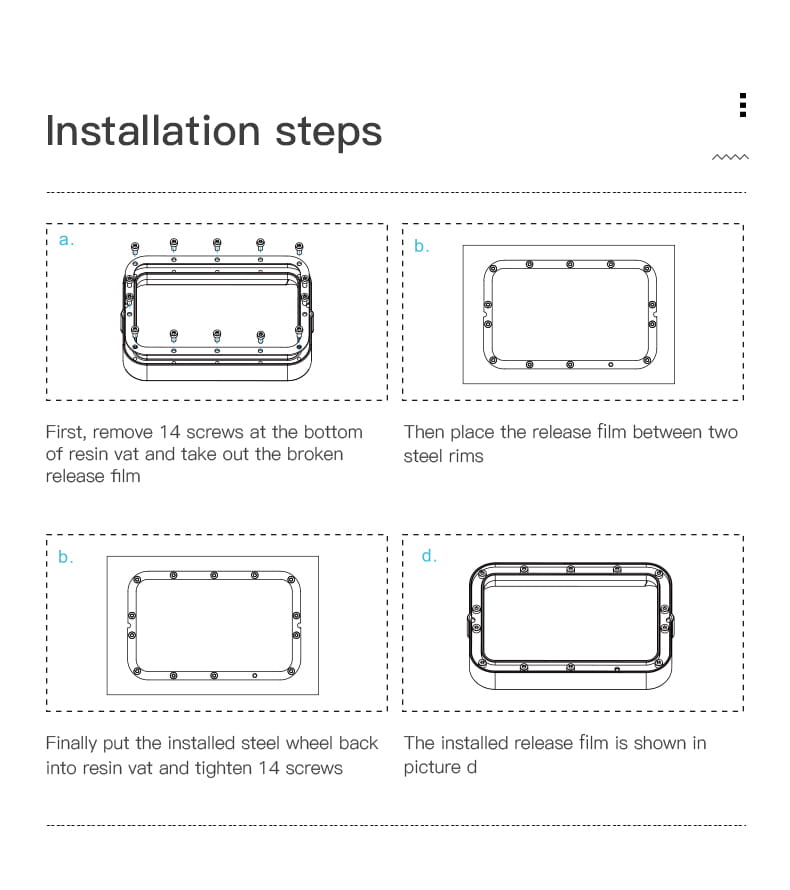

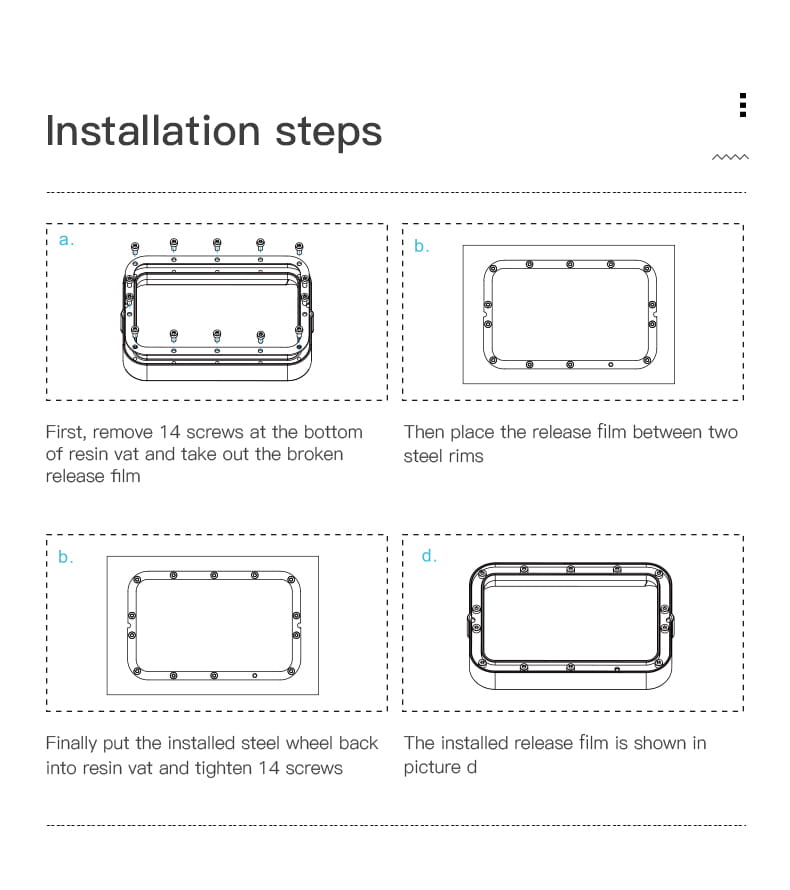

Installation Guide (3 Easy Steps)

1. In step 1, Un-tighten and remove all 14 screws at the bottom of the resin vat. Take the steel wheel out which will then allow you to take out the broken or damaged release film.

2. In step 2, take the new release film and place it in between the steel rims.

3. In step 3, put the steel wheel (taken out earlier) back to its original position in the resin vat and tighten all 14 screws back.

4. The FEP release film is now installed in the resin vat and is ready to use.