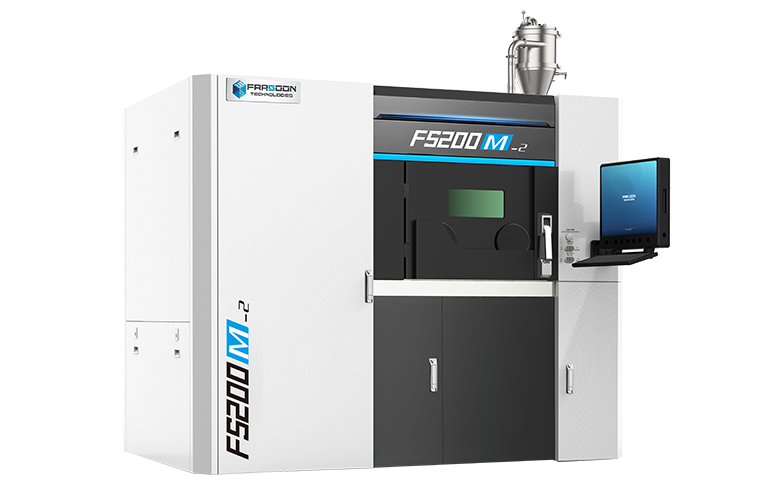

Introducing FS200M-2 System

As a new addition to our medium-sized metal LPBF portfolio, the FS200M-2 is equipped with a versatile build volume of 425 x 230 x 300 mm and powerful dual 500-watt laser configuration. The FS200M-2 is ideal for medium to high volume metal series production and prototypes with fast manufacturing turn-overs rates, versatility, and impressive ROI.

Industrial Applications with FS200M-2

Farsoon’s FS200M-2 is a high-value proposition metal system in pursuit of productivity, cost-efficiency and ease of use for a wide range of industrial applications. The rectangular build chamber is well suited for fabrication of large parts which favor one axis, such as applications in aerospace, automotive and tooling.

Shoe Mold

Machine: FS200M-2

Material: Aluminum

Size: 332 x 138 x 66 (H) mm each

Build Time: 17 Hours

Targeting a series of challenges in traditional shoe sole manufacturing including frequent design updates, low volume customization, and complexity of the pattern, many shoe manufacturers has adopted 3D Printing technology for direct production of end-use shoe sole molds. Rapidly produced on Farsoon’s FS200M dual laser system in only 17 hours, the shoe sole mold has achieved significantly shorter lead time compared to traditional manufacturing. The as-printed part is able to achieve a high surface quality which only need minimum post-processing such as bead blasting before used for injection molding.

Request for a Quote: info@voxelsa.com